The design function touches on the complete steel supply chain, from initial concept design involving the architect through to fabrication and erection of the steel structure and the subsequent operations and maintenance of the building or structure.

Decisions made at the design stage fundamentally influence the complete procurement experience for the steel structure and, as such, are inextricably aligned with our Responsible Steelwork Procurement initiative.

The ASI has significant resources to support design engineers in achieving quality cost-effective outcomes for structural steelwork. It is also important that engineers understand the regulatory framework, workplace health and safety obligations, the specification of steelwork, value engineering and compliance. Read on for more information…

.jpg?variant=FullWidth)

The harmonised Work, Health and Safety (WHS) Act 2011 is overarching and applies to all types of projects, from residential and commercial through to infrastructure and resources. The Act and Regulation places significant shared responsibility and ‘duty of care’ on all parties in the construction value chain – specifically, manufacturers, importers, suppliers, designers and constructors.

In Australia, legislation is established through various Acts of parliament, which, in turn, are actioned through subordinate legislation, typically Regulation. In relation to the building and construction industry, the Building Ministers Forum (BMF) provides strategic policy direction to the preparation of the National Construction Code (NCC) by the Australian Building Code Board (ABCB).

The Safe Design of Structures Code of Practice sits under the harmonised Work, Health and Safety Act 2011 and provides specific guidance to stakeholders involved in the design of a building or structure as to how to implement the requirements of the Act. It highlights the significant shared responsibility for safe outcomes placed on all stakeholders, not just designers. Manufacturers, importers, suppliers and constructors all have a duty of care to ensure safe compliant outcomes. The engineer should inform these parties of their responsibilities in this regard.

Significantly, the Code of Practice speaks to the so-called ‘Safety Report’ as a mechanism to ensure all unusual or atypical aspects of the project are properly and transparently documented and addressed by the responsible party. The ASI strongly suggests that known issues to do with design or product or process non-compliance MUST be documented in the Safety Report to ensure they are addressed adequately and duty of care is actioned by the responsible party.

Visit the Safety in design and procurement and Responsible steelwork procurement pages to find out more about the tools that ASI has developed for all stakeholders in the supply chain.

Australian Standards and various Codes of Practice are, in themselves, voluntary consensus documents representing community expectations regarding quality, safety and risk in the built environment. Australian Standards are NOT in themselves regulation. However, Australian Standards are made mandatory through either:

being called up in regulation, such as in the NCC. Design Standards such as AS 4100 Steel Structures and AS/NZS 4600 Cold-formed Steel Structures are primary referenced documents under the NCC

being called up in the construction specification, in which case the performance requirements of the Standards are established contractually.

Visit the Standards and Design page to find out more.

The structural steelwork specification provides stakeholders in the supply chain a clear indication of what materials and products should be used and the expected quality of the execution (fabrication and erection), in order to ensure that the completed structure meet’s the designers intent and the client’s needs. Together with the design documentation, the steelwork specification is the single most important document to provide all stakeholders a shared understanding of the performance intent of the completed structure and how best to secure that intent. Invariably the steelwork specification references the appropriate Australian Standards and may include additional requirements specific to a particular project.

AS/NZS 5131 provides a technically robust basis for fabrication and erection of structural steelwork in Australia. The ASI has developed and made freely available the ASI National Structural Steelwork Specification (NSSS) and associated Standard Drawing Notes as a convenient implementation tool for engineers and specifiers to action the requirements of AS/NZS 5131.

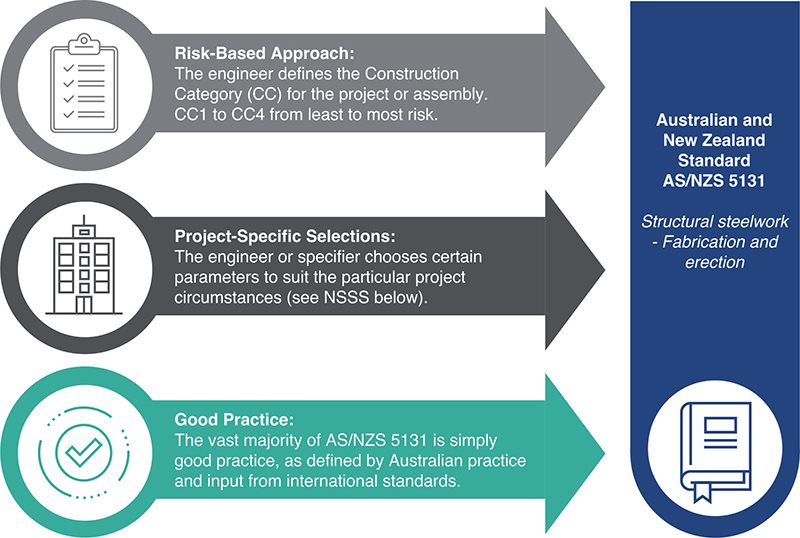

The NSSS is tightly aligned with AS/NZS 5131 and clearly articulates the so-called ‘three-layer model’ from AS/NZS 5131. This makes it very easy for stakeholders to identify project-specific requirements distinct from the general good practice defined in AS/NZS 5131. The graphic below provides further detail on the ‘three-layer model’ in AS/NZS 5131 and the NSSS.

The ASI encourages all stakeholders to implement the NSSS or the equivalent NATSPEC Specifications. A national specification implemented throughout the supply chain will reduce project misunderstandings, re-work and contribute significantly to the productivity of our industry.

The ASI National Structural Steelwork Specification (NSSS) is part of our Responsible Steelwork Procurement initiative and supporting Implementation Toolkit.

Steel is a high-performance solution that provides an unparalleled breadth and depth of opportunity to engineer economical solutions.

More than one reasonable, safe and acceptable solution can often be applied to a particular design. Value engineering asks: 'Which acceptable solution is most economical?' This process also poses the more challenging question: 'Does an entirely different and better approach exist?’ To answer both questions effectively, depth and breadth of experience, together with appropriate tools, is required.

Visit our value engineering Focus Area to find out more.

Compliance of construction products is an industry-wide issue and the solution requires participation from the complete supply chain. Engineers play a key role in responsible steelwork procurement as the primary technical authority referenced by other stakeholders. Engineers define the performance expectation for the completed structure through the technical specifications and design documentation. Compliant steel inputs and compliant fabrication and erection of structural steelwork are prerequisites.

The ASI has created the National Structural Steelwork Compliance Scheme (NSSCS) to provide all stakeholders in the steelwork supply chain and the ultimate client risk-minimised compliant steelwork outcomes. Visit our pages on Quality and Compliance and NSSCS for engineers to better understand the tools that are available.