Australian Standard AS/NZS 5131 and the National Structural Steelwork Compliance Scheme (NSSCS) can be of significant benefit to engineers.

The benefits to engineers include:

Implementing AS/NZS 5131 and the NSSCS for your project is a straightforward four-step process:

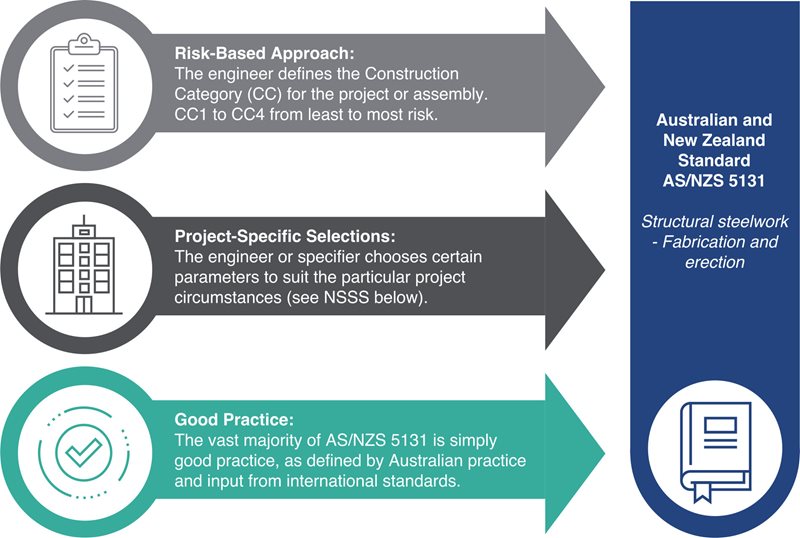

In essence, AS/NZS 5131 defines two ‘layers’ on top of the base layer that represents international good practice:

The ASI has created the new National Structural Steelwork Specification (NSSS) as a convenient implementation tool for industry to ensure that the requirements of AS/NZS 5131 – in particular, the project-specific selections – are consistently and correctly applied.

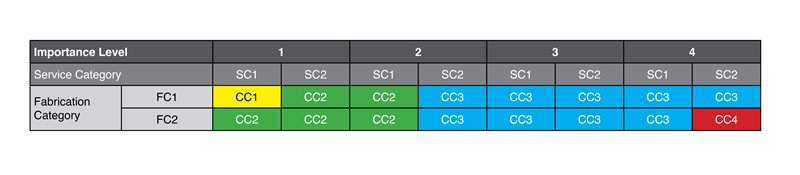

The assessment of the Construction Category for the project or components of the project utilises a simple risk matrix with three input factors:

Having assessed these three input factors, the Construction Category is based on the risk matrix shown below:

The ASI has prepared Tech Note TN011 to assist engineers.

On a project-specific basis, AS/NZS 5131 and associated Standards for steel products require the supply chain to provide documentation to substantiate the veracity of products purchased (steel materials and consumables) and processes undertaken for fabrication and erection. The appropriate competent personnel (architect, engineer, builder, client) must ensure the project submittals required by the Construction Specification and our Australian Standards are obtained and properly reviewed and approved.

Duty of care under WHS Regulation and the Safe Design of Structures Code of Practice provide an unequivocal indication of the shared responsibility for safe outcomes.

The ASI has provided guidance here (PDF).

Utilising certified fabricators will help ensure the project-specific documentation you receive is well-formed, complete and traceable, making the process of satisfying duty of care more efficient and effective.

Engineering certification is required by Regulation to ensure projects meet the requirements of the National Construction Code (NCC) and the performance intent of the construction specification and our Standards.

The engineering certification is usually requested by the building surveyor undertaking the project certification function against the requirements of the NCC.

The ASI has provided building surveyors with a convenient guidance and a checklist. The guidance and checklist provide a fit-for-purpose risk-based approach that all stakeholders in the supply chain should review to avoid problematic building certification outcomes.