Assessment of either the Deemed-to-Satisfy or Performance-Based provisions of the National Construction Code (NCC) will result in a requirement for a level of fire protection (specified Fire Resistance Level or FRL) to be applied to structural members commensurate with building form, occupancy type and member function.

The extent and level of fire protection required will likely be a maximum based on the prescriptive criteria under the Deemed-to-Satisfy approach but can be eliminated or significantly reduced where a Performance-Based approach is adopted.

Regardless of the assessment approach, fire protection to an assessed FRL is usually accomplished through a combination of active and passive fire protection methods:

Active fire protection principally utilises water-based sprinkler systems

Passive fire protection comprises a range of coating systems, cladding with fire rated board, concrete filling (of hollow sections) or concrete encasement.

Active fire protection systems work alongside passive fire protection systems to prevent, retard and suppress structural fires. Active fire protection systems may include:

Fire detection:

Fire/smoke alarm systems detect whether there is fire or smoke in the building.

Manual intervention:

Fire extinguishers and fire fighters are typical forms of manual intervention to fight fires.

Sprinkler systems:

Sprinkler systems help slow the growth of the fire, thereby increasing life safety and limiting structural damage. Sprinkler systems are usually water-based.

Passive fire protection systems insulate steel structures for a prescribed period of time from the effects of the high temperatures that may be generated during a fire. A range of solutions are available, which may generally be divided into two types:

Non-reactive: rely on the inherent insulation property of the applied material. Common types are boards and sprays. Concrete encasement may also be considered a form of non-reactive insulating coating

Reactive: react under the heat of the fire to swell and expand, insulating the structural steel. Intumescent coatings are the best example and come in variants of thin-film and thick-film types.

Spray insulation:

Sprayed insulation, such as vermiculite, is comparatively cost effective and appropriate for indoor areas, which are generally out of sight. Also appropriate for covering complex shapes and details. Spray insulation is best applied on site. Typical logistical issues with ‘wet trades’ and overspray on site need to be managed, as they may impact construction program.

.png?variant=HalfWidth)

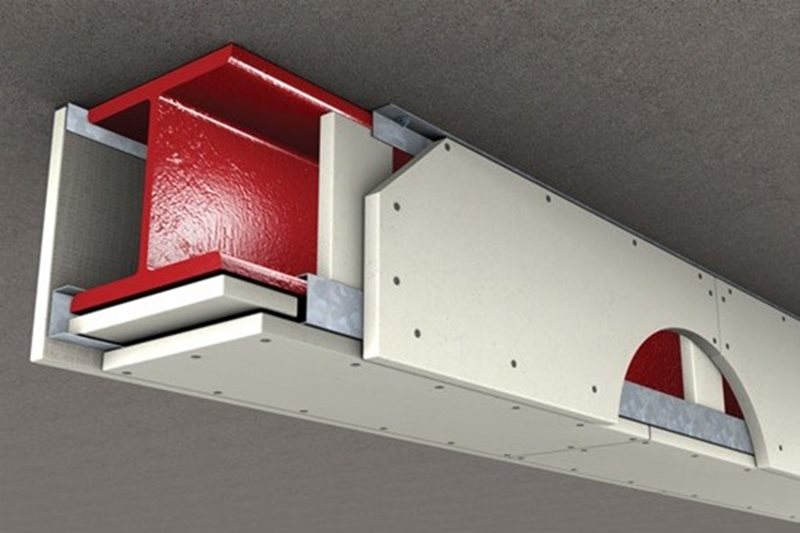

Fire-rated board:

An appropriate solution for indoor areas that are visible – columns, in particular. As a dry trade, logistical issues are minimised. Best applied on site.

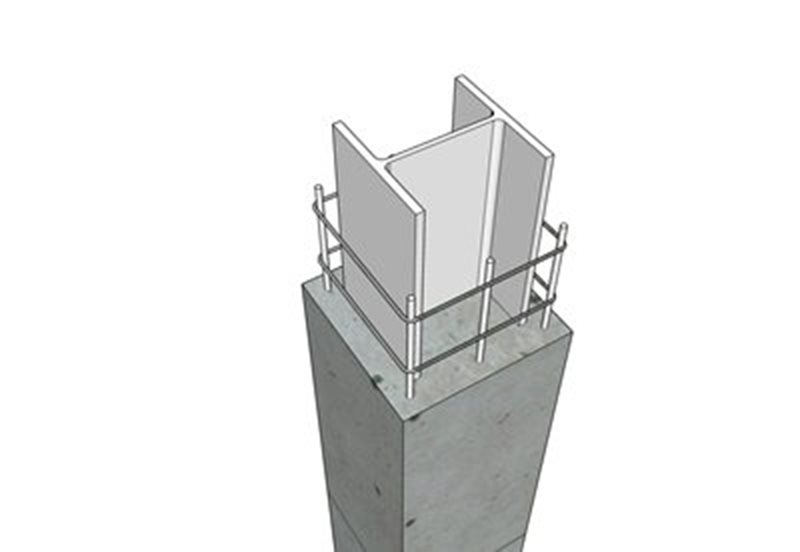

Concrete encasement:

An appropriate solution for columns. The designer may also utilise the structural capacity of the concrete. Best applied on site.

Concrete filling:

Rather than protecting the steelwork, hollow section columns may be filled with either unreinforced or reinforced concrete. The composite column is designed to provide structural capacity in the event of a fire.

Intumescent coatings:

Generally thin film paint like coatings that have the advantage of being able to be applied offsite, much like regular paint. Currently more expensive than other alternatives and most suitable for lower FRLs (<120 min). Specific types can be suitable for exposed and visible areas. Architectural finishes are possible, but attention may need to be paid to the repair of any transport damage, which may dictate onsite application of the coating. Image courtesy Azko Nobel.

.jpg?variant=HalfWidth)