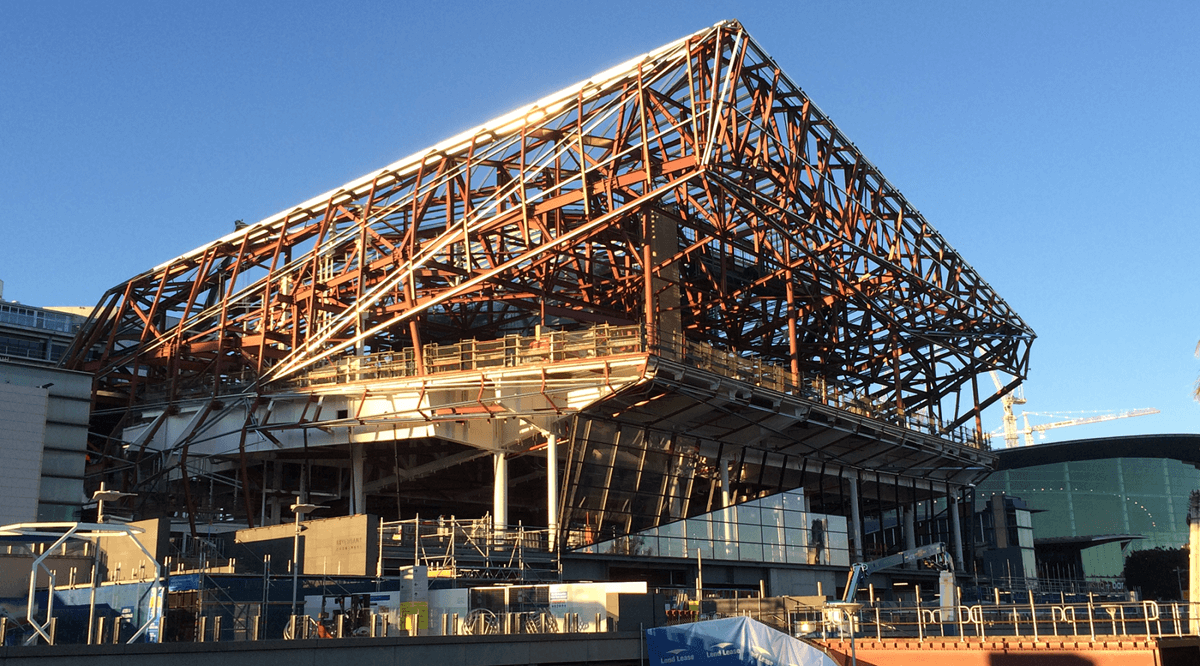

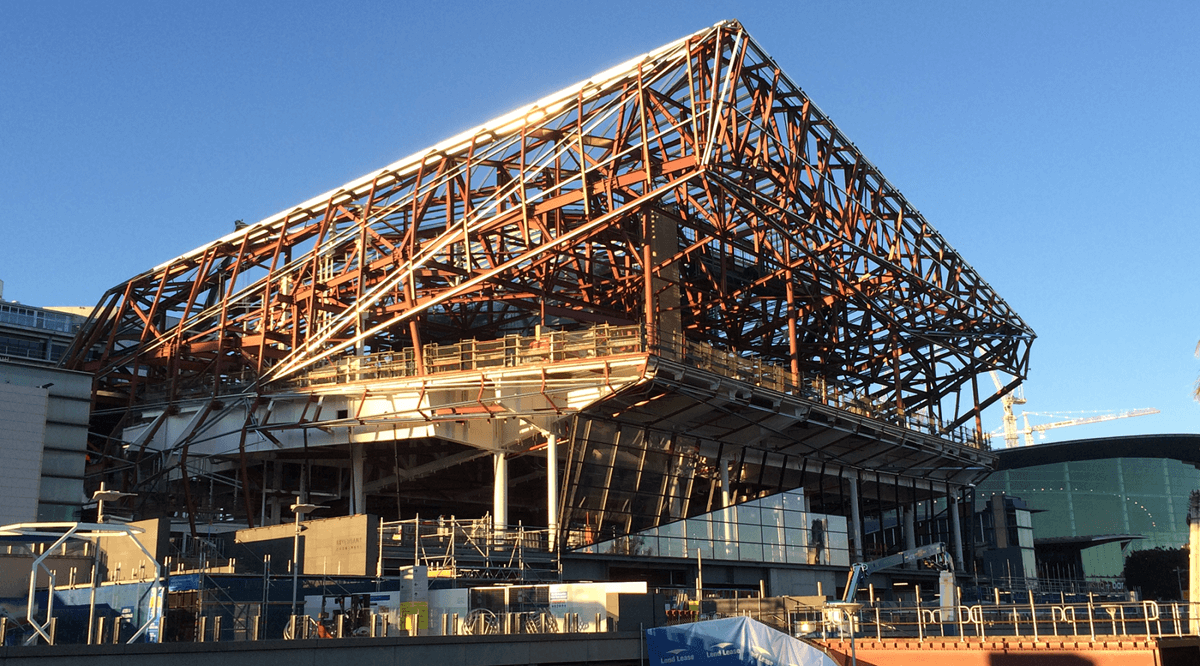

The erection of structural steelwork consists of the assembly of steel components into a frame on site. The components are then lifted and placed into position before they are connected together.

Generally, connection is achieved through bolting but, in some cases, site welding is used. The assembled frame needs to be aligned to within tolerance expectations (usually defined in our Standards) before final bolting up is completed. The completed steel frame may then be handed over for further work on internal floors, external cladding and mechanical and electrical fitments.

The successful construction (including erection) of steel structures safely, quickly and economically starts long before the actual steelwork arrives on site from the fabrication shop. The ‘buildability’ of the structure is influenced significantly by decisions made during the design process long before erection commences.

It is important that designers clearly understand the impact of their decisions. Design for construction is a valid design objective and one that should be considered along with the other usual design objectives in play.

Four design factors to consider in relation to buildability are:

Planning for erection should start at the very beginning of the design process. Such planning should consider the construction sequence, the design factors that affect buildability and site practice in terms of typical erection plant.

In the broader design and planning context, there are three planning factors that affect the buildability of steel structures:

Steelwork erection must also focus on workplace health and safety. The ASI has worked closely with Brookfield Multiplex to produce the Practical Guide to Planning the Safe Erection of Steel Structures (PDF). This Guide sets out practical guidance for the erection of multi-element steel structures.

The purpose of the Guide is to define the planning processes and controls necessary to help support best-practice outcomes that mitigate health and safety risks for all stakeholders associated with the erection of steel structures. The aim of the guide is to inform stakeholders so that better practices as a whole may be considered and implemented and to increase awareness of the legislative requirements in each state for all parties to understand their obligations.