Storage or pallet racking systems are high-performance solutions to store materials, typically on pallets, in an optimally organised format to provide a balance between density of storage and accessibility.

Pallet racking systems are usually categorised from a functional perspective and include the following types:

.jpg?variant=HalfWidth)

.jpg?variant=HalfWidth)

Double deep racking system. Courtesy Dematic.

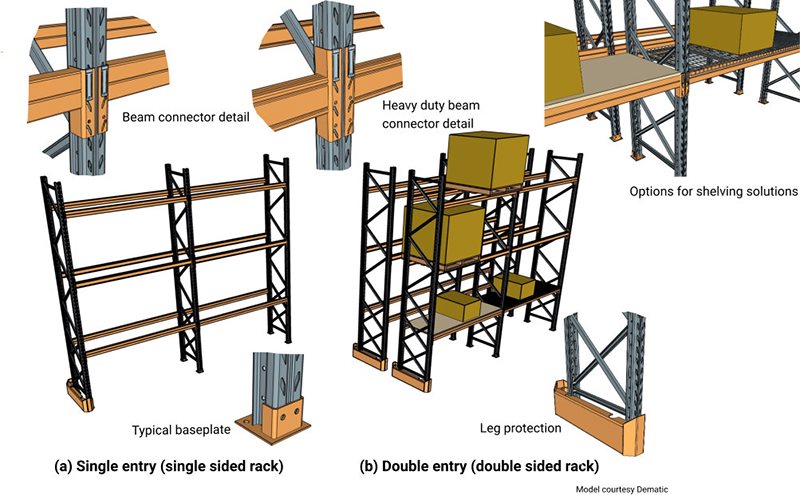

Typical structural systems/members utilised are shown in the figure below:

Australian Standard AS 4084:2012 ‘Steel storage racking’ applies to the design of steel storage racking systems. The 2012 revision to this Standard introduced significant updating of the analysis provisions, allowing the design to be based on analysis types including:

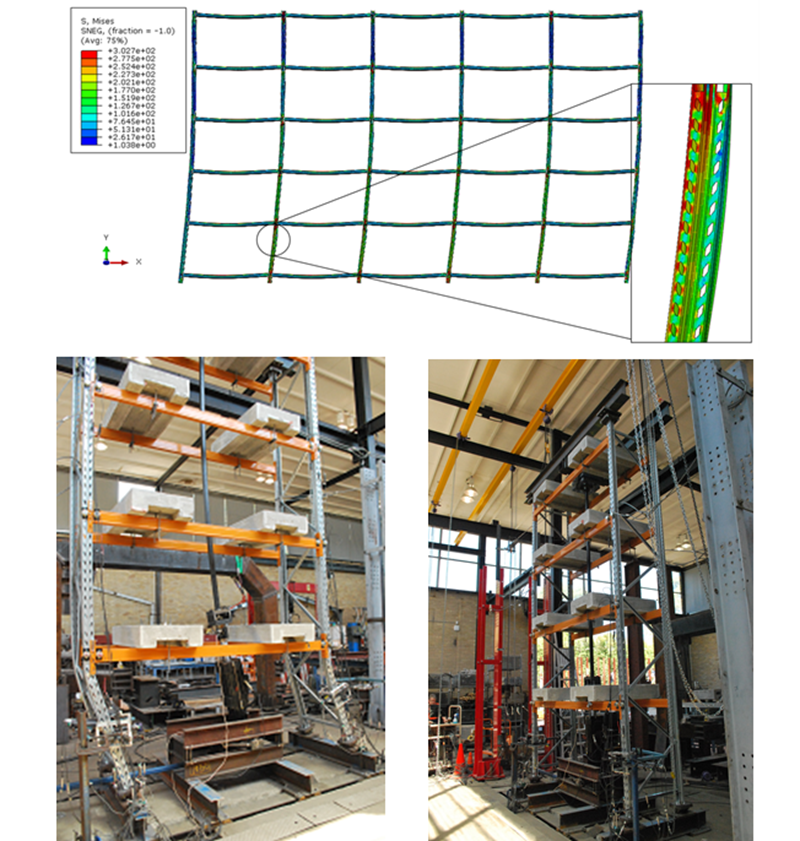

GMNIA, often referred to as 'advanced analysis', incorporates the dominant nonlinear effects and is capable of accurately predicting the behaviour and strength of structural steel frames.

Two types of GMNIA are allowed in the Standard, namely the analysis of structural frames with compact cross sections (GMNIAc) and the analysis of frames with non-compact or slender cross sections (GMNIAs). GMNIAs should be based on a full discretisation of members into finite strips (the finite strip method) or finite elements. Provisions are included for the frame, member and cross section geometric imperfections to be incorporated into the structural model.

Top) Advanced analysis of racking system. (Above) Testing of racking system. Courtesy University of Sydney.

The Standard allows racks to be designed directly with the use of advanced analysis or the use of elastic analysis in conjunction with a structural design Standard.

University of Sydney – Centre for Advanced Structural Engineering (CASE)