A typical building contains a range of different elements and materials, all designed to work together to meet either prescriptive or performance-based requirements mandated for safety of lives and protection of property in the event of fire.

These elements and materials must have a comparable standard of performance and be fit for purpose. To demonstrate this, these materials and elements undergo a severe test that sets a common benchmark. To meet this requirement, standard fire tests have been developed and codified.

.png?variant=HalfWidth)

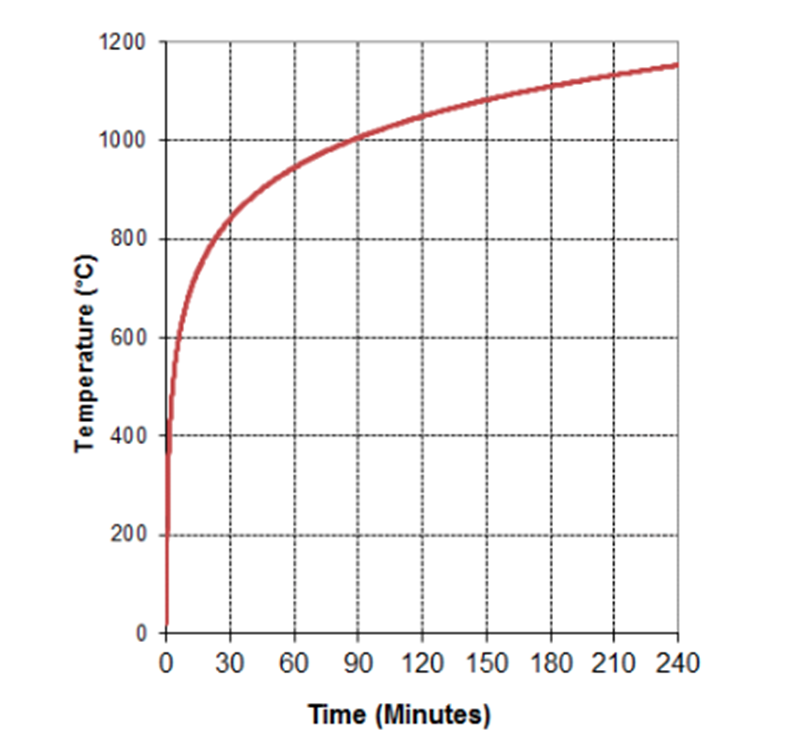

A standard fire test is a test in which specimens are exposed in a test furnace to temperatures corresponding approximately to a standard time-temperature curve. The time-temperature relationship in a standard fire test is internationally recognised and is the same regardless of the test standard used.

While fire tests are standardised in relation to inputs such as the time-temperature relationship, variations in the responsiveness of the thermocouples providing feedback on temperature and differences in the fuel type used (gas versus oil typically) can result in some differences in outcomes.

Australian Standard AS 1530.4 ‘Methods for fire tests on building materials, components and structures – Fire-resistance test of elements of construction’ defines the requirements for the standard fire test in respect of:

The Fire Resistance Level (FRL) is expressed in the above order (i.e. structural adequacy/integrity/insulation). For example, a wall that is required to meet an FRL of 120/60/30 means that the wall must maintain structural adequacy for 120 minutes, integrity for 60 minutes and insulation for 30 minutes, as tested to AS 1530.4.

As well as the standard time-temperature curve for typical building fires, there are also curves representative of hydrocarbon, external and slow-burning fires.

The standard fire test has been in use for over 100 years. It has proven to be of great value in that time and it continues to underpin the testing and assessment of the great majority of fire-resisting materials and components used in buildings.

However, there are limitations to the standard fire test. Time-temperature curves are not particularly representative of what happens in most real fires. In most real fires the temperature increases quickly to a maximum and then rapidly decays and/or moves once the combustible material has been consumed.

Real fires in a compartment are generally either load (combustible material) or ventilation controlled. The extent of combustible material is usually limited and therefore unlikely to cause a threat to structural integrity. If there are low levels of ventilation, the fire will be constrained. In real fires, the location of the most extreme fire will travel, depending on the relationship between fire load and ventilation, meaning that limited areas of the structure will be subjected to the full force of the fire at any one time. The net effect is that no part of the structure of the compartment will be subjected to the full force of the fire for the full time.

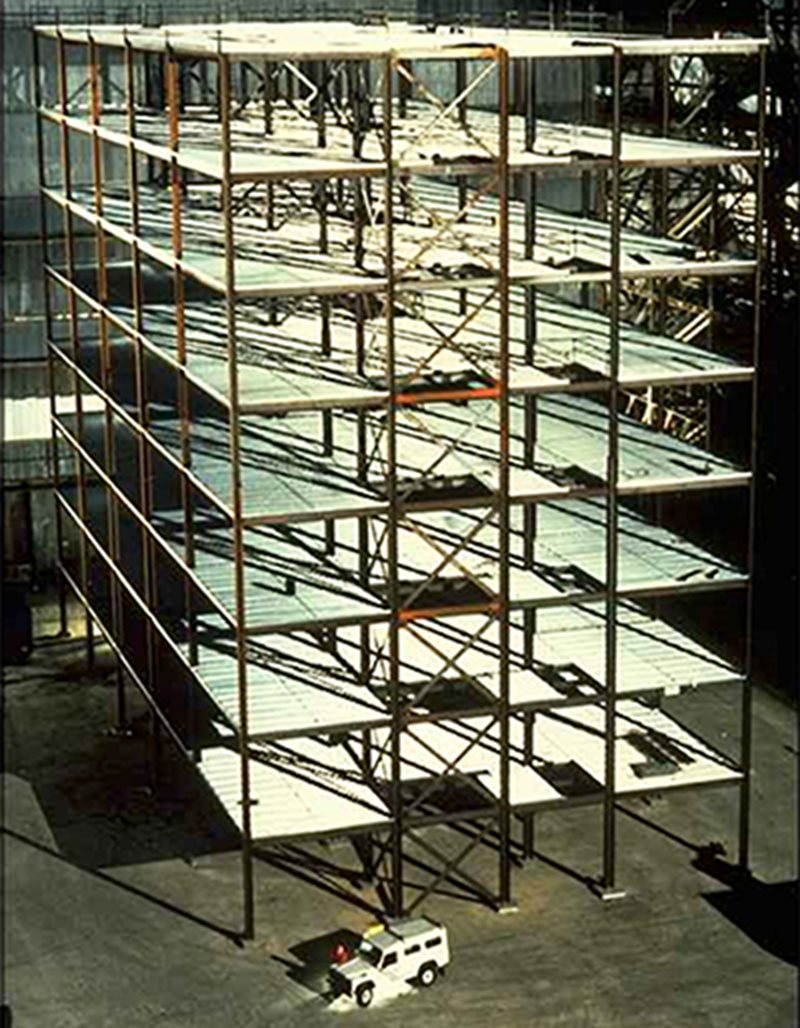

The standard fire test is usually performed on discrete, simply supported elements of a structure, unlike real elements within assemblies of interconnected components and composite steel deck floor structures, all of which typically provide varying degrees of structural continuity. The Cardington large-scale fire tests and an investigation into a fire at a composite steel deck building at Broadgate Phase 8 in London graphically demonstrated that the inherent fire resistance of common structural framing systems is far greater than demonstrated by the simple standard fire tests.

Advances in structural analysis capability have allowed realistic numerical simulation of fire events on structural systems and helped to quantify the behaviour observed in large-scale fire tests.

Cardington large-scale steel frame fire test structure. Courtesy BRE

Column shortening observed at Cardington fire tests. Courtesy BRE.

In recent years, a large number of natural fire tests (tests with fire load made up of material representative of that found in the building concerned) have been undertaken. For example, a global car park fire test programme resulted in a reduced or eliminated requirement for fire rating of open-sided carparks in many jurisdictions. The range of tests undertaken on large assemblies and complete structures has driven a globally pooled understanding of the behaviour of steel structures under fire events and informed performance approaches to Standards and Regulation, supported by structural fire engineering.