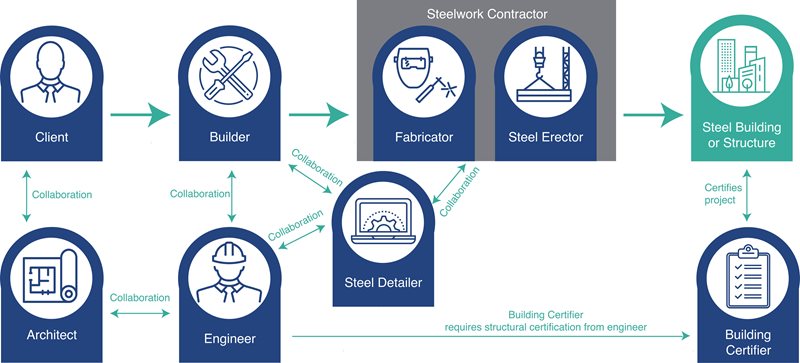

The construction procurement process for a steel building or structure is, in most cases, a straightforward and relatively linear process that can easily be synchronised with the architectural Plan of Work, especially during the early stages involving concept design and choice of structural form.

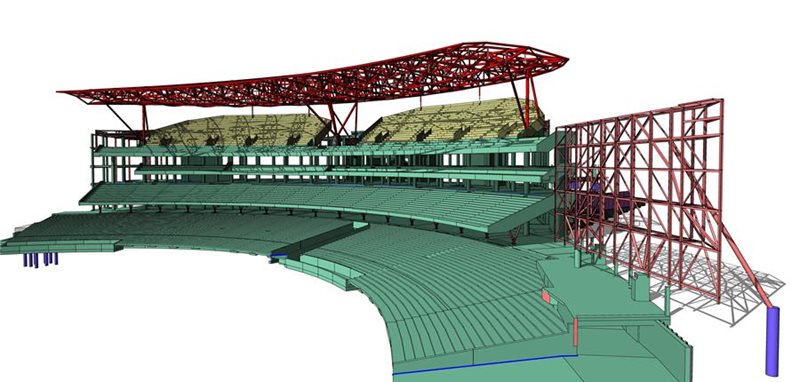

The use of steel, in its many forms, should be considered at the concept design stage. The decision to use steel is strongly dependent on the advantages it offers, including the ability to create architecturally interesting or long-span solutions, savings in the construction program and lighter weight leading to reduced loading on foundations and an ability to retrofit existing buildings.

In its simplest form, the procurement of a steel construction can be thought of as comprising the design process and the construction process in sequence. Ideally, however, the two processes should overlap to ensure the correct translation of architectural intent through the design process and into construction.

.jpg?variant=HalfWidth)

In the context of structural design of steel-framed buildings, there are three main stages:

Refer to the design process page for more detail.

The construction process proper starts with design documentation that is the result of interaction between the architect and structural designer during the design process. The usual stakeholders in the construction process are:

The procurement process may be based on competitive tendering in which the key design information is made available to enable pricing by a range of steelwork contractors. For larger projects the steelwork contractor may be engaged in a two-stage design and construction process, in which Stage 1 enables the contractor to value engineer the solution prior to Stage 2, which is the construction package.